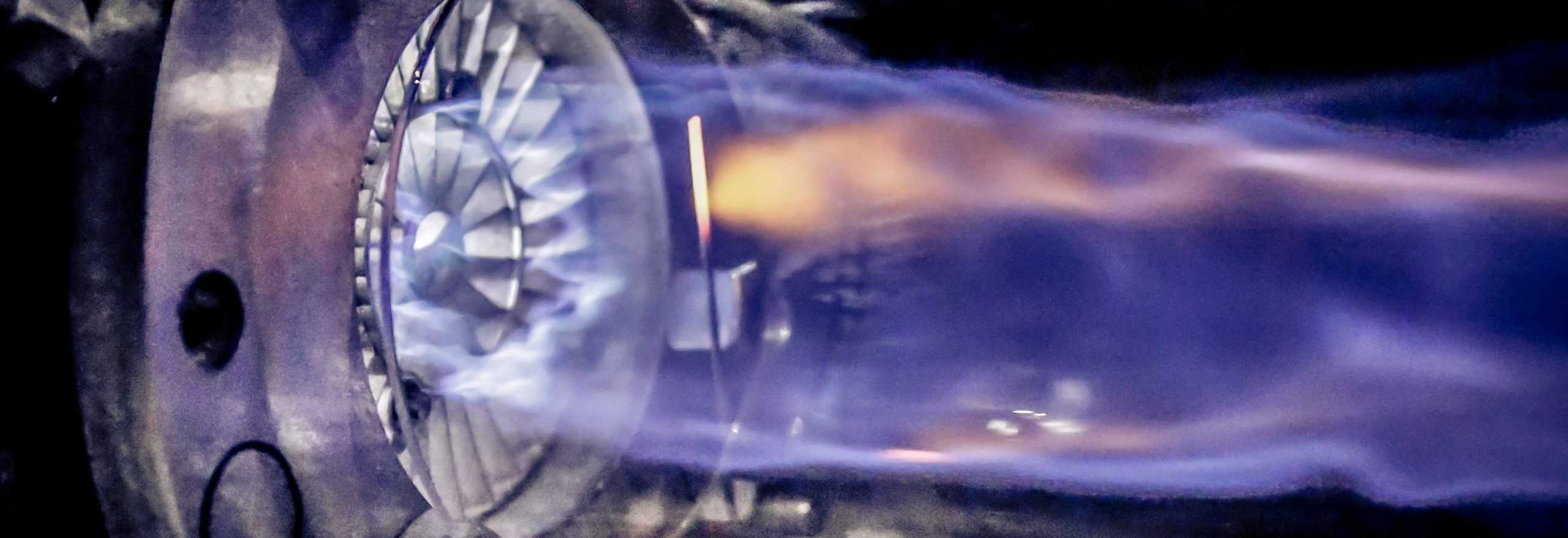

Do you already know our best-in-class? The iRecu dual-fuel recuperative burner stands for efficient heat recovery, maximal fuel flexibility and CO2-neutral production. Winner of the Innovation Prize for Climate and the Environment 2022 and the Efficiency Prize NRW 2019, the world’s first series burner fabricated by using 3D printing, speaks for itself with its unique strengths to date.

What makes the iRecu so special?

- Optimized heat recovery: Efficient heat recovery through optimum preheating of the combustion air. The innovative structure of our recuperator enables highly efficient heat transfer with low pressure losses thanks to optimized flow guidance. The used structure is a complex triple-periodic minimum surface, also known as TPMS.

- Dual-fuel operation: Dual-fuel operation allows flexible switching between 100% natural gas and 100% hydrogen. Until sufficient hydrogen is available for complete decarbonization, the first products can thus already be produced CO2-free. It is also possible to use LPG as fuel.

- Up to 50% fuel savings: With the iRecu® to the energy turnaround in industry. Compared to conventional recuperative burners, the high efficiency of the iRecu® can generate additional energy savings of up to 15%, and up to 50% compared to cold air burners.

Are you interested in our product?

The combination of additively manufactured mixing unit and additively manufactured recuperative burner offers you maximum fuel flexibility at your thermoprocessing plant. Do you have any questions about our product or would you like to make an appointment with us? Please feel free to contact us! You can find more information about the iRecu here: