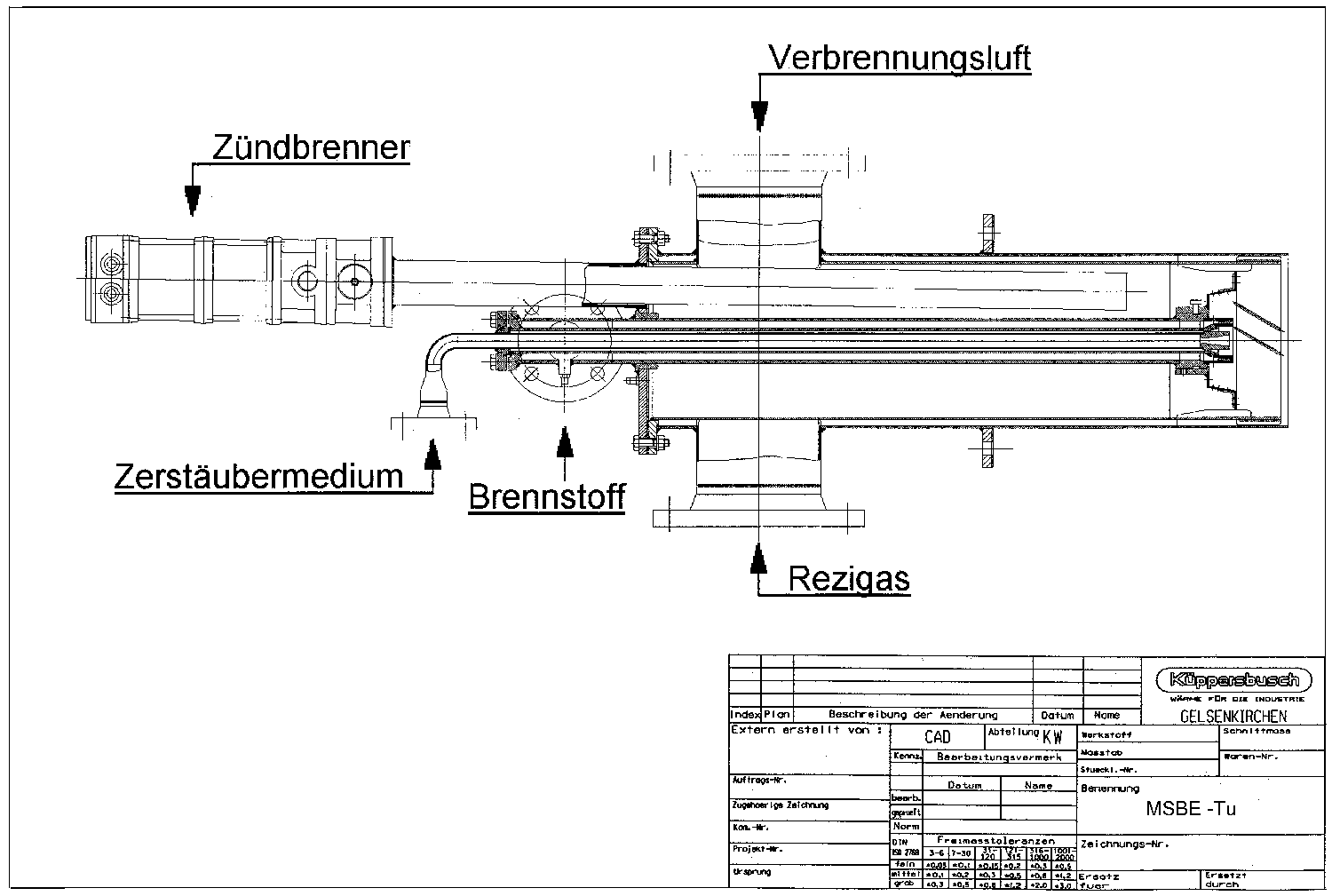

The high heat release and high/ low pressure air burner is especially designed for the combustion of liquid and gaseous residues from all industry sectors. The atomisation of liquid fuels is achieved through an auxiliary atomizing medium (compressed air, steam, natural gas) and the combustion air addition results from the low pressure principle.

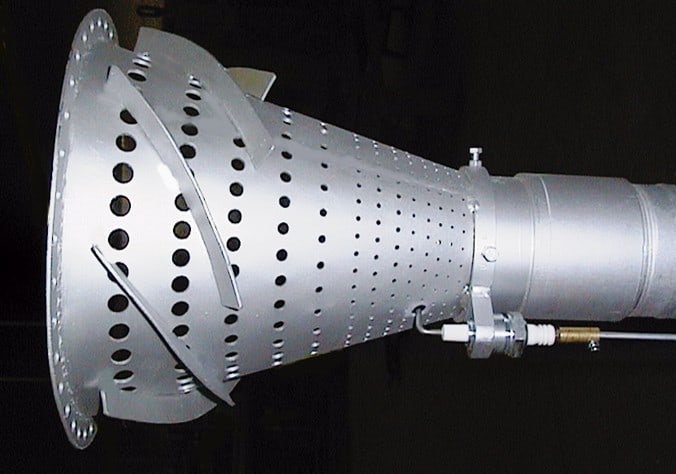

The ceramic burner port (separate or integrated in the whole lining of the heat generator) is used for the flame stabilization and gives the flame size and shape. Another modification of the flame form is possible with an adjustment of the burner injection mixer. The burner is constructed with modulus in order to burn up to three different gaseous and/or liquid fuels at the same time.

The flame ignition is done with a gas-electric pilot burner or with a direct spark ignition owing to a special highvoltage igniter. The flame supervision is obtained owing to an ultraviolet diode or an infrared detector according to your needs. The control of the different fuels and of the adequate combustion air quantity is made in a complete automatic way with modulations depending on the plant loadsignal. The burner equipment and the materials are determined in accordance with the required operating conditions.