The low – NOx multifuel burner type KSBZ can be used for industrial process in boilers, thermal oil heaters, industrial furnaces, hotgas generators, waste incineration, fluidised bed furnaces, afterburning chambers etc. . lt’s use in combustion chambers with negative or positive pressures allows a reliable operation when properly adapted to the combustion chamber’s size and shape.

The combustion of all usual liquid or gaseous fuels, exhaust vapours or residual fluids from different chemical process etc. can be controlled up to almost 100%. With the appropriate additional modules, pulverised fuels can also be included in the combustion process.

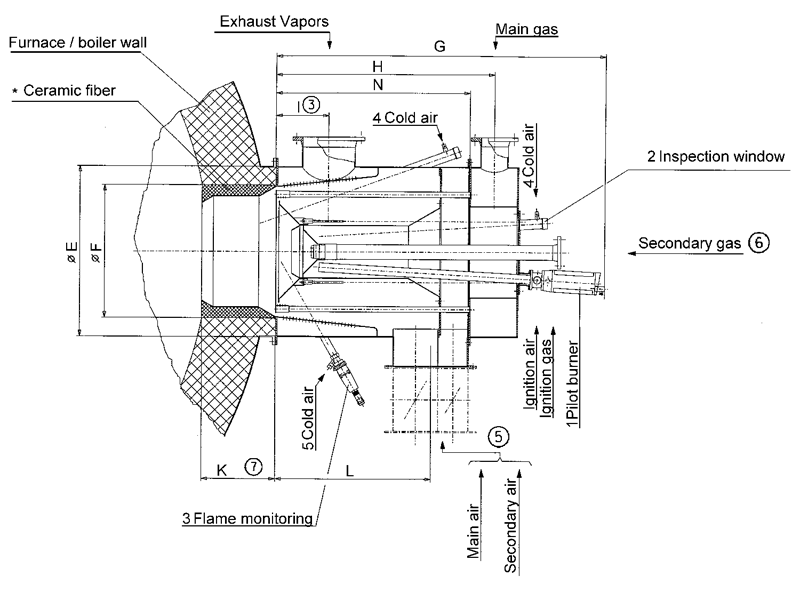

The burner can be run with atmospheric or preheated air up to 400°C. The burner is a fully automatic unit with a separate combustion air fan. The belonging fuel, supply and security systems as weil as the “measuring and control equipments” are delivered in each case project-oriented and in the wished variations.

All fuels as weil as the primary and secondary combustion air are fully automated controlled with a programmable fuel-air ratio controller tested and in compliance with the European norms.The regulation is made by modulations. The burner range of regulation is provided for 1 :10 (15) with gaseous fuels, for 1 :6 (8) with liquid fuels or for 1 :3 (5) with dust. Depending on the kind of fluid fuel, burners can be delivered as pressure, compressed air or steam atomizer. A simultaneous combustion of several liquid or/and gaseous or dusty fuels is possible at any time.

According to the emission standards, different modules, which reduce the emissions, are integrated in the burner in a way that all legal requirements are respected. The ignition is done gas-electrically through a gas pilot burner and the flame monitoring is guaranteed owing to the adequate UV or IR sensor, in compliance with the EC-norms.

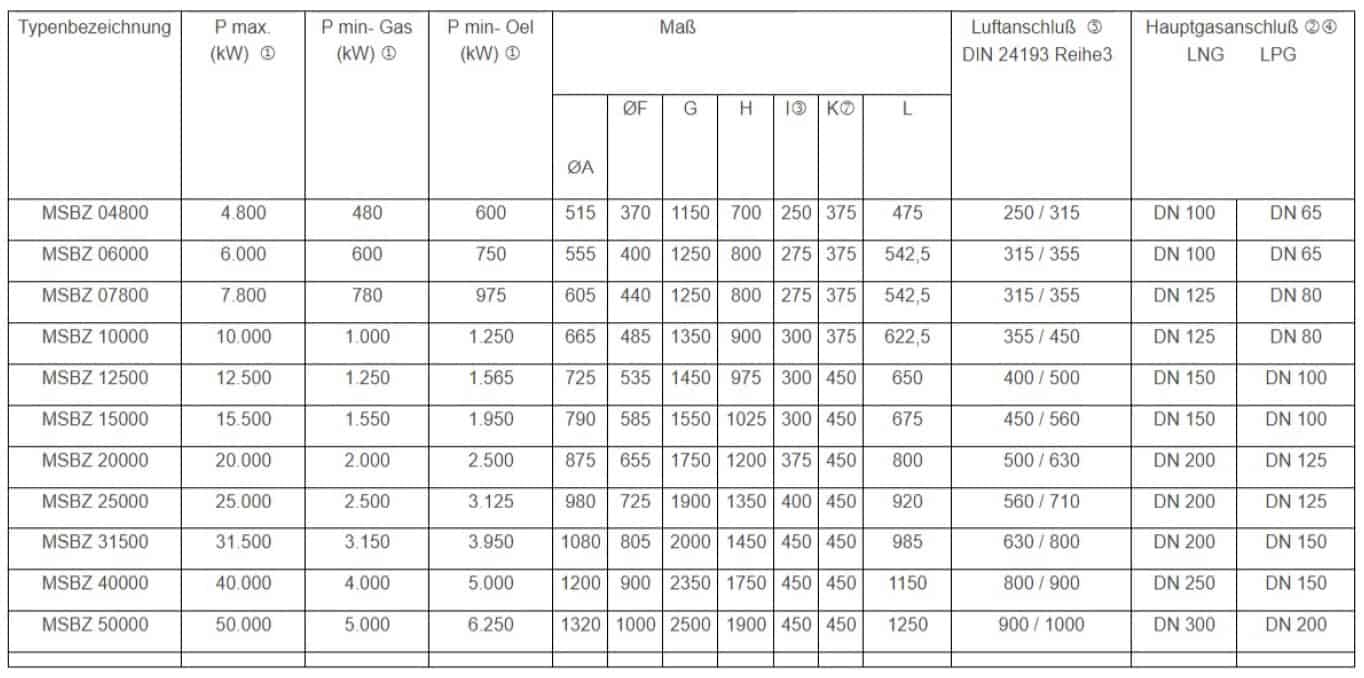

At your wish, special materials can be used in the construction of the burners or individual modules. The burner assemblage and size will be determined in relation with the required capacity and your special needs. Please, give us detailed information.