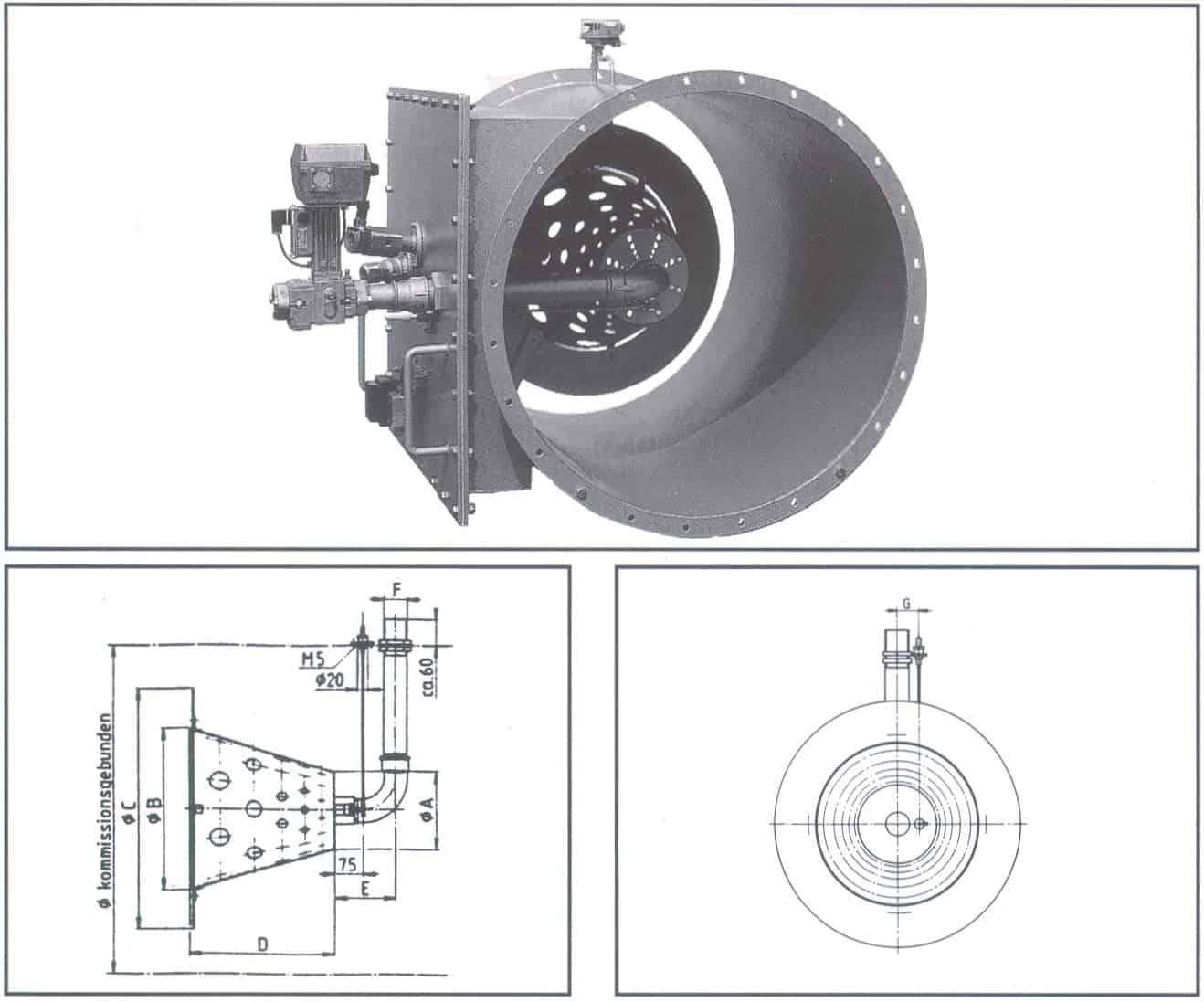

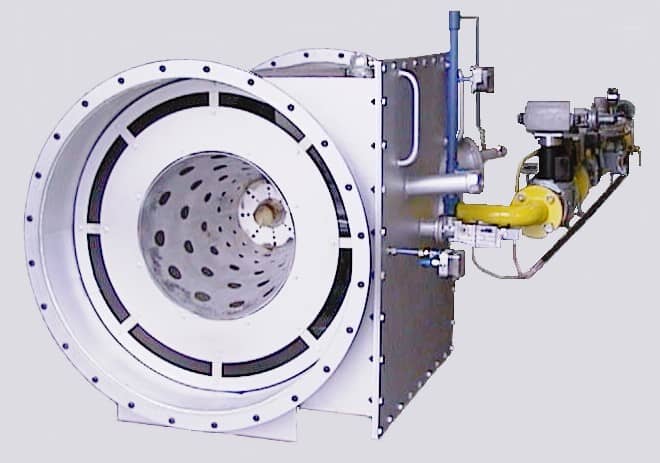

The diffusion burner DFR is a surface burner specially developed for the direct heating of air – with the admixture of combustion gases – and for the direct thermal afterburning of exhaust gases. The diffusion burner operates without an external supply of combustion air.

The oxygen required for combustion is extracted from the process gas to be heated. For this reason, the process gas must contain at least 17 % oxygen. The burner is mounted directly into the process gas duct. A special combustion chamber is not required.

Some of the process gases are introduced into the mixing zone of the burner at high speed through the bores of the mixing cone, where they mix with the fuel gas (no premix burner – thus absolute safety against flashback).

The graduation of the mixing cone bores and the associated dosing of the amount of oxygen entering the mixing zone guarantees perfect burnout and excellent flame stability over the entire control range (up to max. 40:1 depending on the application).

To ensure that the diffusion burner functions properly, a uniform flow velocity of 16 – 40 m/s of the process gas over the entire duct cross-section is required. With this burner, all commercially available cleaned gases such as town, district, natural and liquid gas as well as their mixtures can be burned with air.

The type DFR burner can be equipped in such a way that fully automatic operation is possible and it complies with EN 746/2 with regard to the functional sequence and safety equipment. Use in the vacuum range down to -10 mbar and in the overpressure range is possible.

Ignition takes place by means of high-voltage ignition sparks, protection electronically by means of a UV diode or an ionizing bar. In conjunction with an electronic control unit. The burner is preferably regulated continuously, whereby only a gas-side regulation is carried out. Switchgear and control cabinets, in which all parts required for control are installed ready for connection, can be supplied.