When it comes to low-pressure, small gas burners, Bunsen nozzles have advanced significantly:

• although small in design, their output is ve1y high

• they are tolerant to impact and insensitive to condensate

• they are made of steel and thus are highly reliable (SEP nozzles are also available in brass)

• the !arge cross-section of the exit bores makes clogging almost iJnpossible

• they are blow-back proof

Bunsen nozzles are perfectly suited for bottom to top burniJ1g of the flame. For complete combustion to take place, they require not only primaiy air but also require secondaiy air that must be supplied to the flame from below. Depending on the size of the heated surface, there must be sufficient space below the burner for the supply of the combustion air.

The installation of a flow safety device according to TRV is necessaiy, if the exhaust gases are channeled into a chimney stack. In order to dimension the nozzle bore for gas mixtures, we requfre the upper calorific value and the gas pressure, as well as the exact composition.

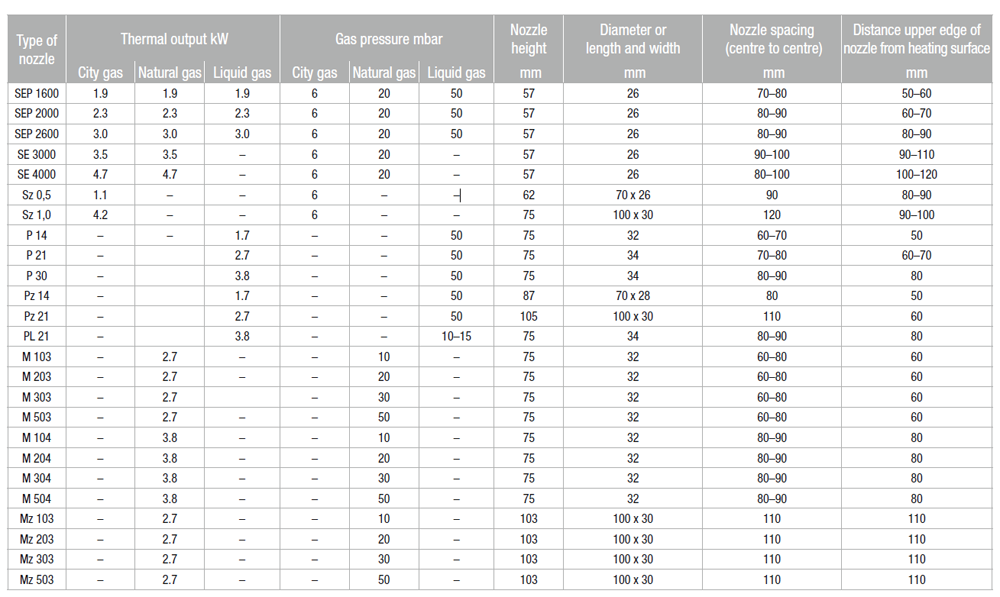

Under consideration ofthe spacings listed in the table, the Bunsen nozzles can be assembled based on the requirements into longitudinal, riJ1g and star formations or any other configuration. We produce standard low-pressure burners in a variety of designs; please ask for the respective brochures.

Amongst other things, the Bunsen nozzles described here are used for the following applications:

• Low-pressure star-type burners

• Low-pressure ring burners

We plan, manufacture and deliver complete heating equipment for the entire industry. Please ask for additional documentation.

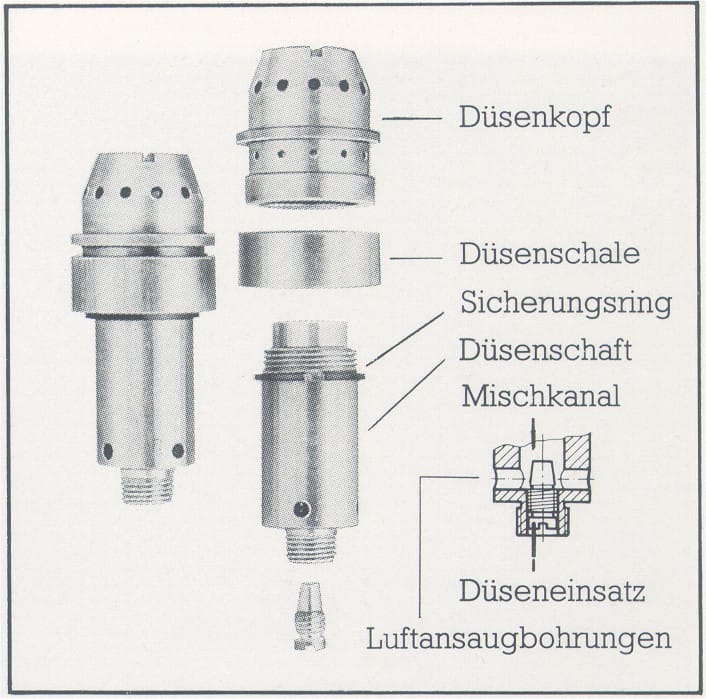

Bunsen all-gas nozzle SEP

In order to convert from city gas (grid gas) to natural gas, a small nozzle insert must be installed. lt can be simply screwed into the burner’s shaft. The flarne is very stable, which is achieved by a flame-retaining ring that branches off from the main mixture’s flow beneath the main flame.

The strength of the flame can be modified and set to a variety of limits by simply replacing the nozzle insert. The wide-ranging flames make the over ignition from nozzle to nozzle easier and at the same time promote a uniform secondaiy air supply through the combustion chamber.

Conversion to liquid gas and all other common gas/air mixtures are easy. When using liquid gas, the shaft and the nozzle insert rnust be replaced. Gases with the same Wobbe number (e.g., rieb gas and nat11ral gas) do not require the replacement of this nozzle insert. The flames of both gases burn with the same strength and without any conversion.

When using city gas (grid gas), natural gas and liquid gas the strength of the flame can be adjusted by changing the bore size of the nozzle insert increments from 1.9 to 3 kW). The nozzle can also be supplied for 3.5 kW and as a special design for 4.7 kW. However, it is not available for liquid gas.

Bunsen-M-nozzles for natural gas and Bunsen-P-nozzles for liquid gas

The Bunsen-M- and Bunsen-P-nozzles are suitable for the combustion of natural gas and natural gas/air mixtures or liquid gas and liquid gas/air mixtures.

Bunsen SZ-MZ-PZ nozzles for town, natural and liquid gas

In contrast to nozzles with star-shaped flames, Bunsen SZ-MZ-PZ nozzles are also suitable for burnout with horizontal flames. They are particularly suitable for heating side walls of containers, whereby the container bottom must remain unheated.

For gas mixtures, we need the upper calorific value, the gas pressure and the exact composition to design the nozzle bore.

The Bunsen nozzles can be assembled as required into long, circular and star burners or any other shape, taking into account the distances listed in the table. We manufacture low-pressure burners in a wide variety of designs as standard; please request brochures on this subject.