26 Oct Additive manufactured recuperative burner system

Kueppers Solution GmbH, GWI Gas and Heat Institute Essen

Kueppers Solutions GmbH emerged from the spun-off “Küppersbusch Fachbereich Wärmetechnik”. As a technical supplier with special expertise in 3D printing in thermal process technology, the company develops innovative solutions for industrial heat generation. The objectives are the more efficient use or substitution of conventional fuels and the improvement of emission values. For the best possible concepts, Kueppers Solutions cooperates closely with universities, institutes and companies – for example with the Gas and Heat Institute Essen (GWI).

AdReku: Saving energy and reducing emissions

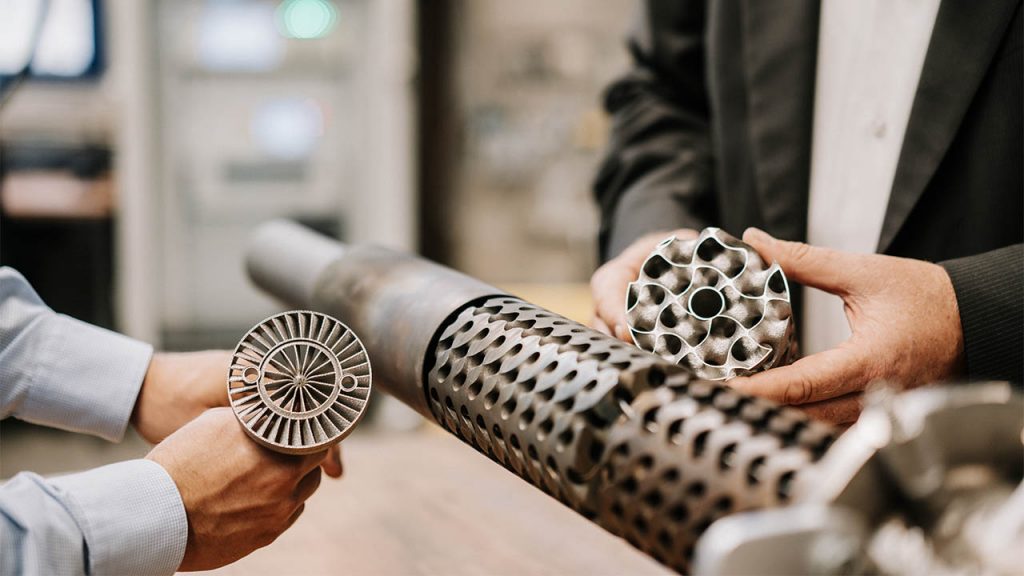

The additive recuperative burner (AdReku for short), which uses waste heat to preheat the fuel gases in order to increase efficiency, achieves an efficiency of over 80 percent when preheating the combustion air, which is more than 15 percent above the state of the art. This is made possible by an innovative combination of materials and a complex geometry in the recuperator, which is created using 3D printing. A 3D-printed gas mixing system also prevents excessive increases in nitrogen oxide levels in the exhaust gas. The fuel requirement and emission output of industrial thermoprocessing plants can thus be reduced considerably. Series of measurements at the Essen Gas and Heat Institute (GWI) have verified the parameters, and the first test plants with the new technology are scheduled to be installed in 2021.

Key facts about the project

- Project participants: Kueppers Solutions GmbH, Gas and Heat Institute Essen (GWI)

- Project start: July 2019

- www.kueppers-solutions.de

You will find the article listed here together with further picture and video material under the following link: https://innovationspreis.gas.info/house-of-innovation/forschung-entwicklung/adreku/